Our Tactical Process Analysis, Engineering Support and Lean Practices Support are key to our ability to contribute to your improved ROI through cost savings and higher productivity, improved operating efficiency, reduced carrying and handling costs, reduced working capital and reduced workforce requirements.

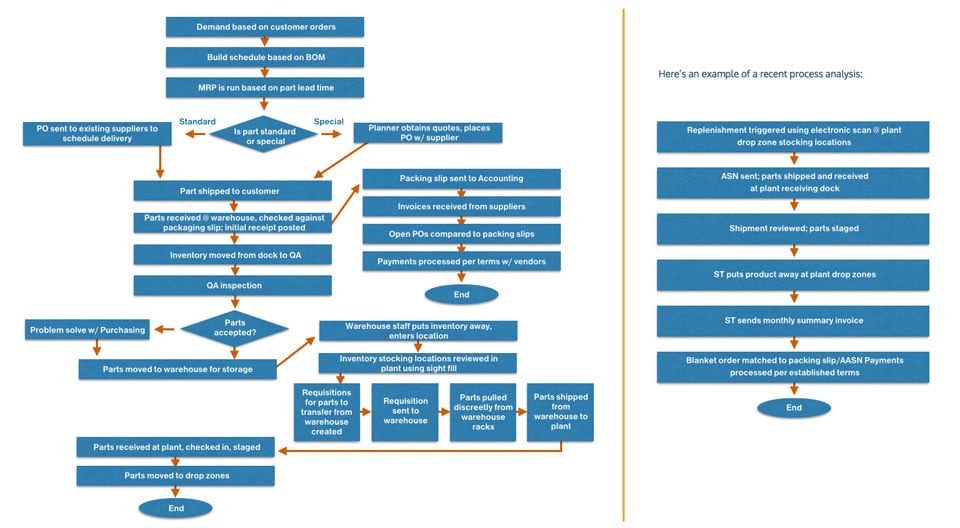

Our Tactical Process Analysis provides a consultative approach to identify and drive improvement in the total cost of acquiring a customer’s class "C" components. In its simplest form our team focuses on reducing time, transactions (labor), inventory and space allowing our partners to increase their efficiencies and ultimately improving their profitability. Although our global and world class ability to procure and deliver anywhere in the world at competitive prices is second to none, our value proposition comes alive when combined with the often double-digit savings achieved through our Tactical Process Analysis.

Our process includes:

Our recommendation resulted in significant changes:

| Previous Process | Recommended Process |

|---|---|

| Multiple vendors | One vendor |

| Separate purchase orders/shipment | One purchase order |

| Increased # of invoices | Summary invoice per month |

| Increased receiving costs | Reduced freight |

| Increased receiving inspection | Reduced warehouse space |

| Increased freight | Certified inspection |

| Increased warehouse space | Electronic replenishment |

| Increased carrying charge | Optimal inventory levels |

| Transactions (need discussion) |

Before and After Cost Comparison:

| Description | Customer's Current Annual Cost | Supply Technologies VMI Annual Cost | Annual Savings |

|---|---|---|---|

| Purchasing administration | $50,000 | $5,000 | $45,000 |

| Warehouse labor | $30,968 | $0 | $30,968 |

| Plant material handlers | $18,000 | $0 | $18,000 |

| Purchase orders | $62,510 | $35 | $62,475 |

| Payables/accounting | $26,610 | $180 | $26,610 |

| Freight & warehouse space | $203,150 | $62,700 | $140,450 |

| Inventory carrying | $117,631 | $0 | $117,631 |

| IT/purchasing system | $24,000 | $0 | $24,000 |

| TOTAL | $533,490 | $67,915 | $465,134 |

The pursuit of technical perfection is nowhere more important than in the quality assurance, engineering and testing of the billions of parts and materials we supply every year to our customers.

It is what drives us to continually seek out better and more efficient methods of enabling you to build the highest quality end use products at the lowest possible total cost – and therefore increase your competitive advantages and opportunities.

Quality Assured

As part of our supplier development and retention process – and to proactively self-regulate our own quality standards – our Technical Services team performs the industry’s most rigorous component testing, both at supplier facilities and our regional worldwide inspection centers. In fact, in many instances, customers have Delegated Initial Sample Approval (DISA) responsibility to Supply Technologies, thus eliminating redundant inspection activities and customer resource requirements.

Our commitment to quality is embodied by our being third-party registered to the following standards: ISO 9001, ISO 14001 and ISO 17025.

Designing Engineering Efficiencies

A critical function of our Technical Services team is its ability to work closely with customers' engineers to design efficiencies into existing and new products. An extension of their own departments, we bring experience in over 100 industries to facilitate design development, improve assembly line ergonomics, and reduce costs.

The Value Analysis/Value Engineering (VA/VE) services provided by our Application Engineering Specialists include:

At our dedicated Tear-Down Facility we literally tear down our customers’ products every day. With the goal of developing the most technically superior end-use products and solutions available in the marketplace, through improved designs, elimination of redundant parts, and assembly efficiency improvements, we enable your engineers to focus on their next innovation.

Utilizing advanced technologies, including 3D, CAD imaging for both end-use product and piece-part design, we have proven time and again that our ultimate value extends beyond individual piece prices.

Another way Supply Technologies maximizes value to customers is by adhering to Lean principles in an effort to continuously improve methods and processes.

We apply Plan-Do-Check-Act (PDCA), Kaizen, and Business Process Improvement (BPI) practices, with the result of measureable and sustainable improvements to our customer-focused value stream. Efforts with current customers include:

With standardization of processes, relevant metrics and communication between all employees at all levels, our Lean approach enhances our ability to provide fast response to our customers’ changing demands.

Whether we’re servicing your day-to-day operations, working with your Lean team, or assisting you as you begin the Lean journey, we’re single-mindedly focused on efficiency.

Supply Technologies and Total Supply Management are trademarks of Supply Technologies LLC.

All other trademarks are the properties of their respective companies.