Seth Swanner, Vice President of Sales and Marketing of Supply Technologies, shares his views on the industry and the dangers concerned with “custom” VMI programs that are being marketed by many competitors.

In my earlier blog post I discussed some of the key aspects involved in deciding on the right vendor managed inventory (VMI) program for your business – because the last thing your company needs to do is incur additional costs moving into a program that was initially supposed to save you money. In taking it a step further, I’d like to outline some of the benefits realized when your VMI program is developed based on the specific needs and processes of your organization rather than built around an off-the-shelf solution.

In my earlier blog post I discussed some of the key aspects involved in deciding on the right vendor managed inventory (VMI) program for your business – because the last thing your company needs to do is incur additional costs moving into a program that was initially supposed to save you money. In taking it a step further, I’d like to outline some of the benefits realized when your VMI program is developed based on the specific needs and processes of your organization rather than built around an off-the-shelf solution.

-

Better consumption control and parts velocity management

-

Reduced costs across multiple areas of your business

-

Improved cash flow through creative programs such as “pay on consumption”

-

Resource reallocation opportunities to focus on other key initiatives within your supply chain

-

Improved time management/efficiency

-

Improved quality standards and component traceability

-

Minimized and mitigated inventory liability

-

Reduced interruptions on production lines

-

Increased manufacturing square footage and production floor space

-

Streamlined Just-In-Time (JIT) solution for your production floor team

Good custom VMI programs are designed to meet your specific needs and to offer much more than just the service of supplying parts. Successful VMI providers work with their customers to identify the best solutions ranging from dock-to-dock to full consumption based models. Their desire is to partner with our customers to ensure that they thoroughly understand how parts, materials, labor and delivery options create negative impacts on their bottom line, because these costs are real and they matter to the overall profitability of our customers.

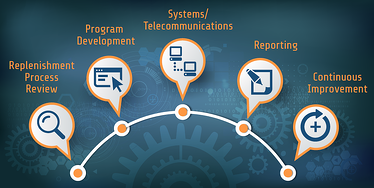

To accomplish these objectives, we provide an intense program called Tactical Process Analysis to truly drill into the costs that are impacting your business. This process is designed specifically to quantify the “current” state and to quantify a “future” state that offers continuous improvement across all areas of costs and production fulfillment.

There are some cases where a full vendor managed inventory program isn’t the right choice for your business. If you’re experiencing any of the following, our Tactical Process Analysis Team (T.P.A.T.) will be happy to review your current program with your team:

- Line shortages, stoppages or downtime

-

Limited manufacturing floor space

-

Excess inventory in your plant

-

High number of POs

-

Obsolete inventory

-

Disorganization of procurement process, storage and/or retrieval

-

Inflexible distributors – limited commodity support

-

Quality and/or traceability Issues

-

High costs associated with handling, freight, ownership, acquisition

-

Multiple vendors that provide the same types of commodities

-

The need for a supplier who has a global footprint

-

Under-resourced and in need of more internal labor personnel

-

Need for part rationalization, standardization or consolidation

The best way to understand where potential efficiencies exist is to benchmark your current process and scrutinize all of the hard and soft costs associated with each step. From there, evaluate the VMI options available to you against that benchmark along with the implementation plan to make sure the turn-over doesn’t end up costing your organization or worse, shutting down production. We encourage you to download our Tactical Process Analysis Worksheets, they’re a great tool to start your evaluation process.